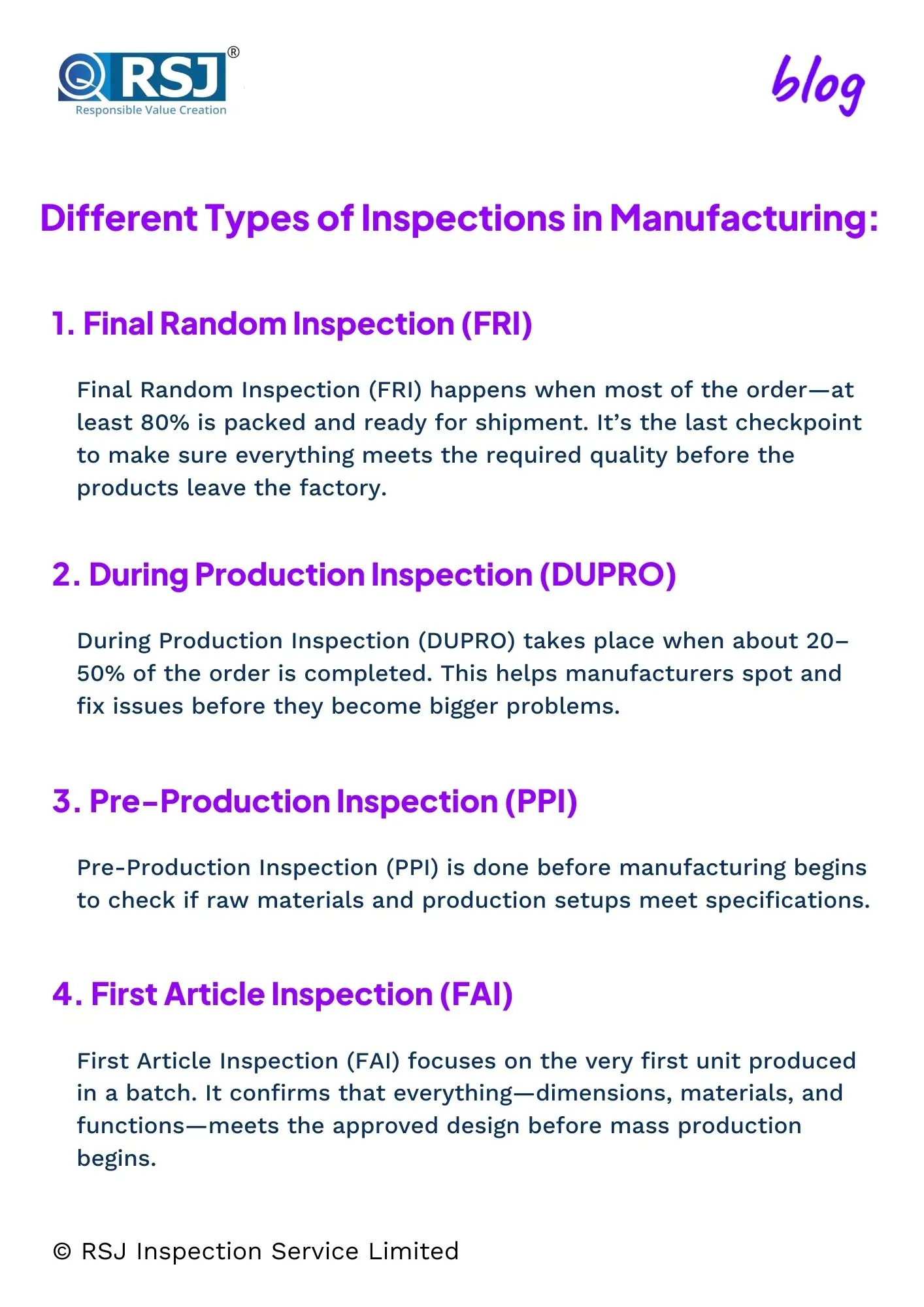

Understanding Different Types of Inspections in Manufacturing

Ensuring quality in manufacturing is critical to maintaining customer satisfaction and avoiding costly mistakes. That’s why inspections are conducted at various stages of production to catch defects early and keep everything on track. In this blog, we’ll break down four essential types of inspections: Final Random Inspection (FRI), During Production Inspection (DUPRO), Pre-Production Inspection (PPI), and First Article Inspection (FAI).

Let’s dive in!

List of Major Inspections are:

1. Final Random Inspection (FRI)

What is FRI?

Final Random Inspection (FRI) happens when most of the order—at least 80% is packed and ready for shipment. It’s the last checkpoint to make sure everything meets the required quality before the products leave the factory.

Example:

Imagine a factory producing 10,000 jackets for a clothing brand. Before shipping, inspectors randomly pick samples from different cartons to check for stitching quality, sizing accuracy, and overall appearance. If they find major defects, the shipment gets held back for corrections.

2. During Production Inspection (DUPRO)

What is DUPRO?

During Production Inspection (DUPRO) takes place when about 20–50% of the order is completed. This helps manufacturers spot and fix issues before they become bigger problems.

Example:

A ceramic factory is making dinner plates for one of the repeated brands. Halfway through production, inspectors noticed glazing defects on some plates. Since the problem is caught early, adjustments are made, saving time and reducing defective stock.

3. Pre-Production Inspection (PPI)

What is PPI?

Pre-Production Inspection (PPI) is done before manufacturing begins to check if raw materials and production setups meet specifications.

Example:

A shoe manufacturer is about to start production on a new sneaker line. Before cutting the first piece of leather, an inspector examines the material’s thickness and texture to ensure it matches the brand’s quality standards. If the leather is subpar, the supplier is asked to replace it before production kicks off.

4. First Article Inspection (FAI)

What is FAI?

First Article Inspection (FAI) focuses on the very first unit produced in a batch. It confirms that everything—dimensions, materials, and functions—meets the approved design before mass production begins.

Example:

An automotive company develops a new brake pad model. The first piece off the production line undergoes detailed testing for durability and performance. Once it passes, full-scale production moves forward with confidence.

Why These Inspections Matter?

- Prevent costly rework by detecting issues early.

- Maintain high quality and keep customers happy.

- Ensure compliance with industry standards and regulations.

- Improve efficiency by reducing production delays and waste.

RSJ Inspection Services – Your Trusted Quality Partner

At RSJ Inspection Services, we help businesses maintain high-quality standards at every production stage. Our services include:

- Fabric Inspection

- First Article Inspection

- During Production Inspection (DUPRO)

- Final Random Inspection (FRI)

Don’t let defects ruin your production! Contact RSJ Inspection Services today for professional inspection solutions that keep your products flawless, and your customers satisfied.

We are One Click Away!

Contact us today to save your time and improve your product quality with RSJ Inspection Service!